In the world of spray foam and coatings applications, precision is not just a requirement; it's the foundation of quality and safety. Graco's Reactor Ratio Assurance System emerges as a revolutionary solution, designed to enhance the accuracy and reliability of these critical applications.

The Essence of Ratio Assurance

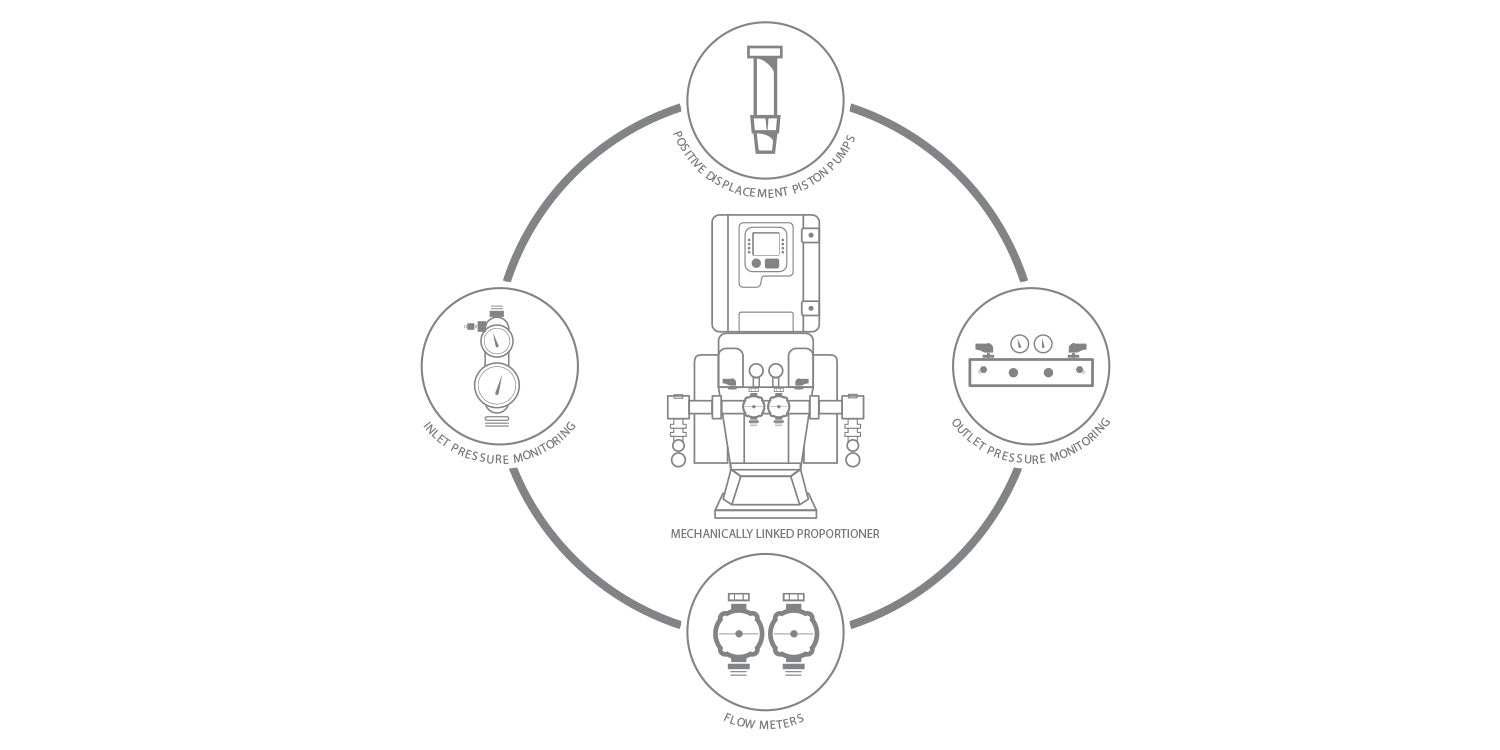

At the heart of the Reactor Ratio Assurance System lies a commitment to ensuring the correct material ratios. This system utilizes advanced technology, including mechanically linked positive displacement piston pumps, to maintain consistent material flow. By closely monitoring pressure ratios and utilizing precise flow meters, the system provides real-time assurance that the material mix is always on point.

Benefits: Why It Matters

For contractors and builders, the Reactor Ratio Assurance System is a game-changer. Its ability to detect even minor deviations in material ratio prevents costly rework and ensures the integrity of the application. This translates to peace of mind for homeowners and builders, knowing that the end product meets the highest quality standards. Furthermore, the system's quick detection capabilities mean equipment issues can be addressed promptly, minimizing downtime.

Real-World Impact

In practice, this system has proven invaluable in various settings, from residential to commercial projects. Its precision has led to enhanced efficiency, improved quality control, and a significant reduction in material waste.

A Step Towards the Future

Graco's commitment to innovation is clearly embodied in the Reactor Ratio Assurance System. For those in the spray foam and coatings industry, embracing this technology means taking a significant step towards more efficient, reliable, and high-quality applications. It's a reminder that the right tools not only make a job easier but also elevate the standard of the work done.